Why Choose Pulp?

Moulded Pulp Advantage

- Lower impact on environment

- 100% Recyclable

- Cushion and protective properties for your packaged goods

- Durability

- Less subject to price fluctuation than traditional oil based packaging products

Product Systems

Available:

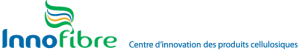

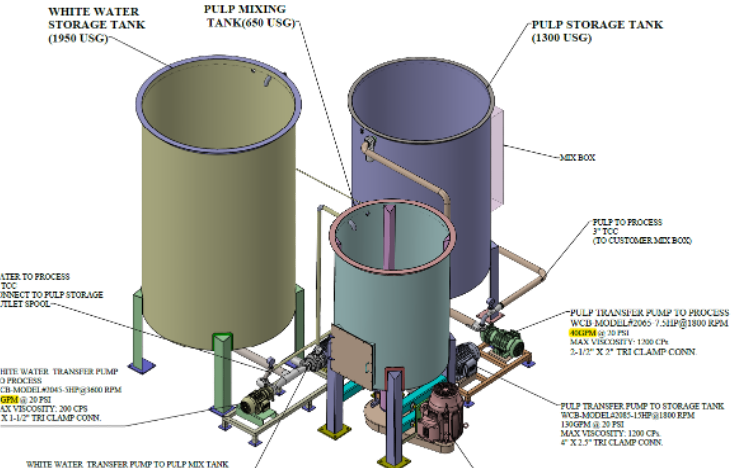

Pulp-Skid

Pulp-Smart Consulting Development Inc. is pleased to present our “Pulp-Skid” this portable unit that has been developed for lab scale development of moulded fibre products, it can be used with our TF-1 moulding system or others to charge the forming tank with the customer’s preferred fibre. The unit can be manual or be integrated into an HMI or functions via a small control panel.

The customer’s prepared 4% solids to water is diluted to a percentage by selection, to which water is added and the slurry is circulated until required by the forming tank on the system. The unit provides flexibility in the development of fibre products for the pulp moulding industry.

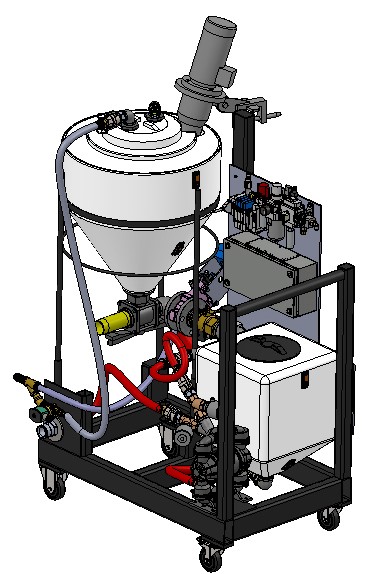

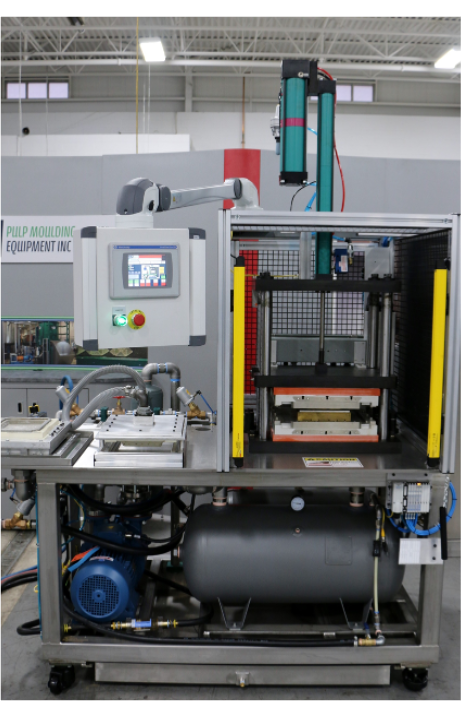

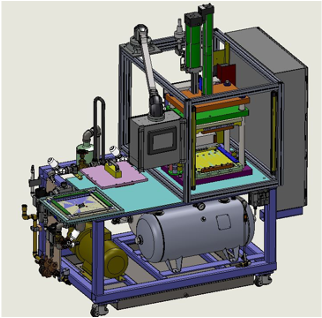

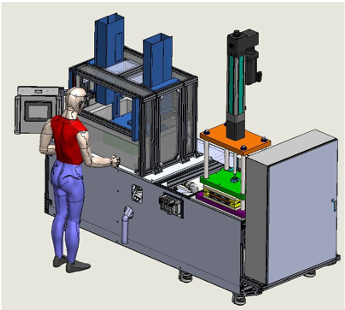

Dual Layer Moulding Lab scale Unit

A unique forming station, that integrates and pneumatically actuated rotary, vertical unit, and side shift for presentation to the forming tank that will hold the fiber substrate (approx., the substrate will be mixed via 2 stationary mixers mounted to the each holding tank to ensure slurry uniformity during forming. The forming station will be designed to accept the tooling maximum part height will be limited to 76.2mm (3.0”) X max 355.6 X 355.6. A 7.5 HP 230V 50Hz Liquid Ring Vacuum pump station mounted to an extruded aluminum frame will be used to draw substrate against the forming tool and an air accumulation tank will be used for blowing off the product to the technician. All functions will be variable and accessible via the HMI. Safety light curtains will be integrated into the guarding to protect the operator and an access door will be provided from the rear of the station.

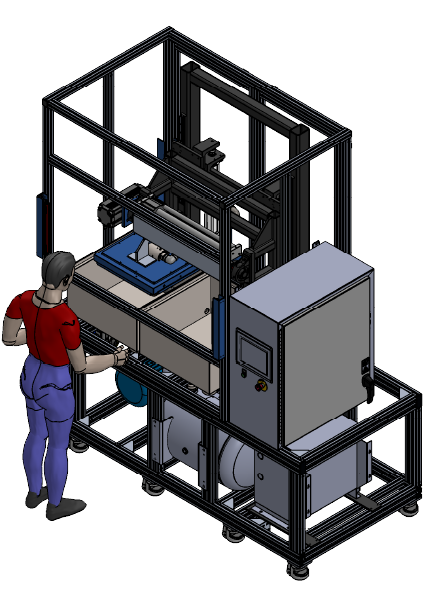

Servo Controlled Hot Press 30T

(686.5Kn) it can be customized to higher press forces, with a holding force of 325Kn for 30 sec max and temperature to 200 degrees C and control. The servo unit will utilize a loadcell and potentiometer for monitoring force and distance as well as the use of the variable force time hold features of the system. The force profile will be determined in detail at engineering approval.

Heating system using a 5000W flat plate heater design to increase the replenish time during the press/drying process and direct the heat to the tooling. A custom design will be used to insulate the area. Thermo couples will be used in the upper and lower platen to monitor over temperature and process temperature. The heater plate will be designed for easy removal for maintenance purposes.

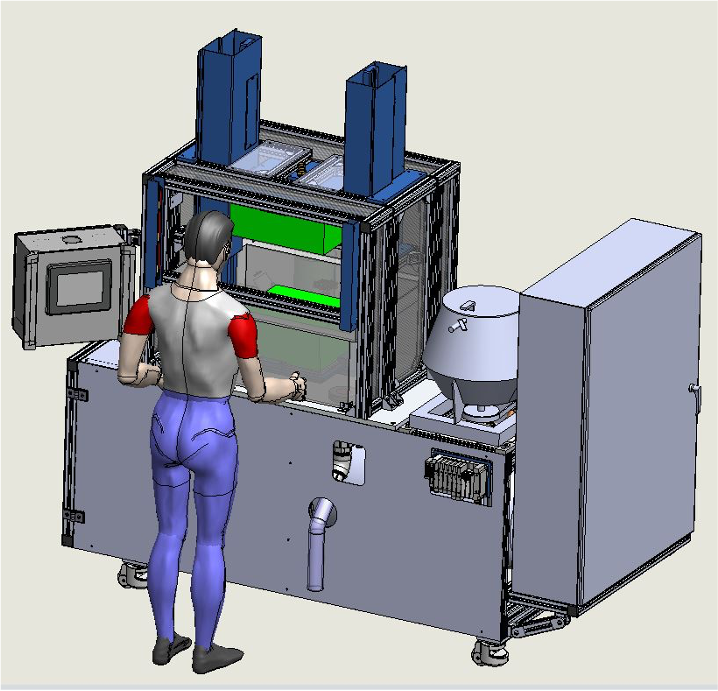

Type 3 Sample Machine

Forming Station & Thermo Press

for product development and samples.

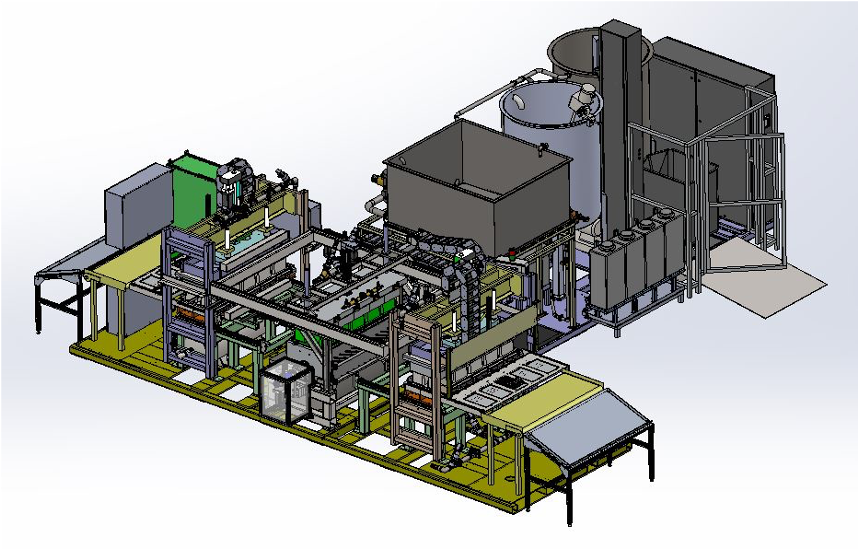

Type 3 Thermoform Tableware Production Machine

Pulp Preparation with Dual Press

Type 2 Transfer Moulder Sample Machine

With integrated pulper

Type 3 Thermoform Sample Machine

With 10 ton servo press for product development and samples.

Type 3 Thermoform Sample Machine

With integrated pulper and 10 ton servo press for product development and samples.

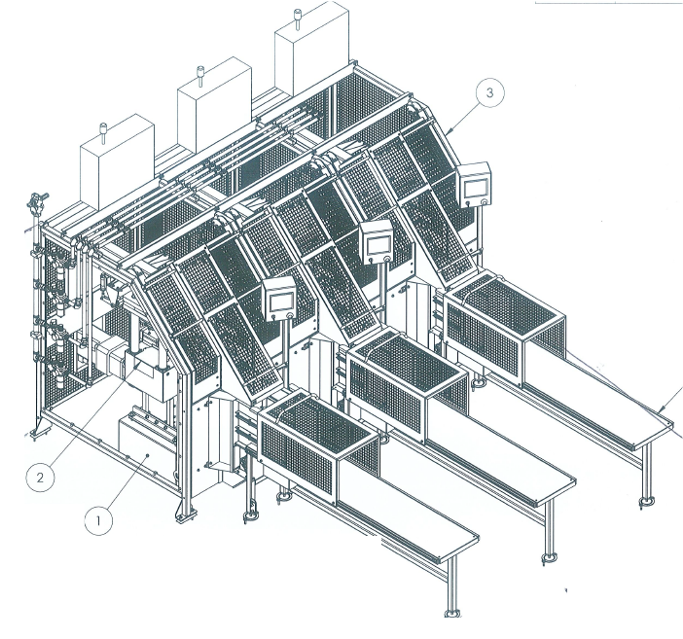

Type 2 Production Machine

150-350kg per hour rotary machine for egg cartons, egg trays, wine packaging and industrial packaging .

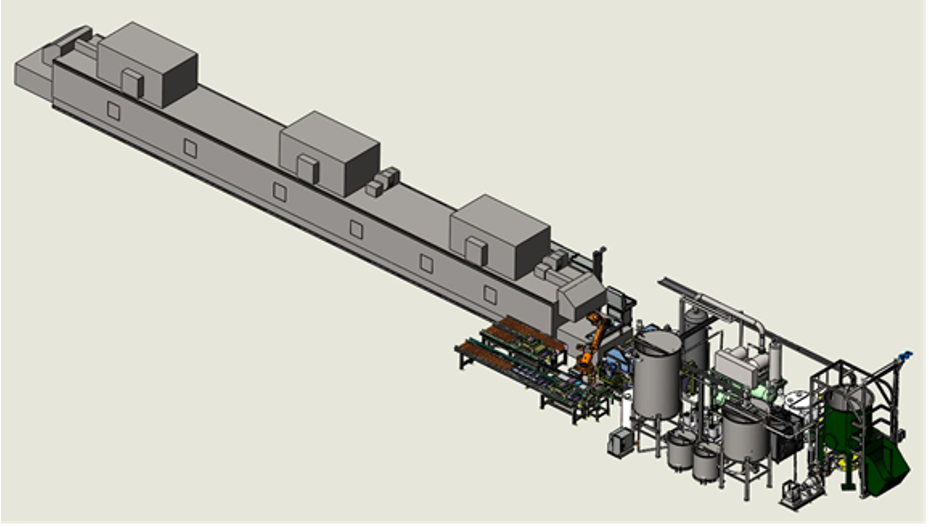

Type 2 In-Line Hot Press

System for Egg Cartons

Complete Facility Design

Type 2 In-Line System for Egg Cartons

Complete Pulp System Design & Integration

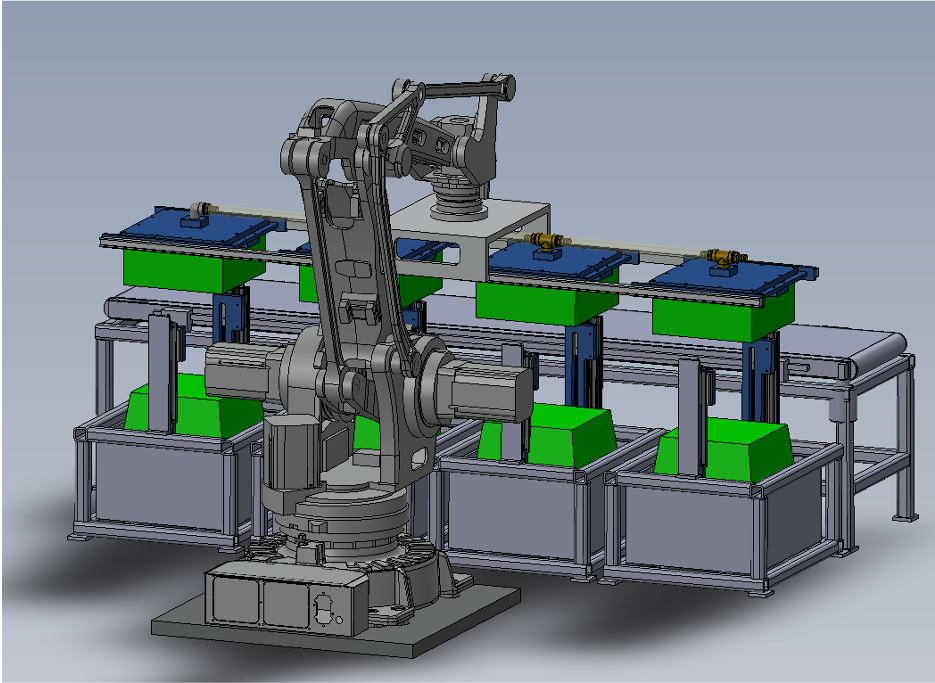

Complete Robotic Forming, Transfer Design & Integration

Pre-Owned Products Available:

-

Moulding Machine (4 Face Type 2)

-

Vacuum Pumps

-

Miscellaneous Pumps

-

Consistency Meter